Amana Tool

End of Year 15% off sale on select Amana top selling blades: MB10800, MB10800C, PR1040C, 610504, 610504C, 512961, 610800, 610800C, 610601, 610601C, LB10801, LB10801C, 610600, 610721. Hurry! Sale ends December 31, 2025.

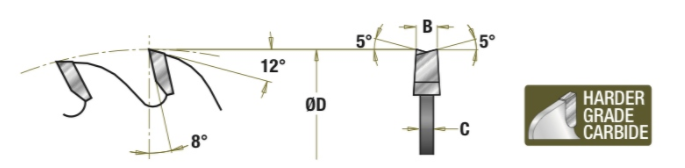

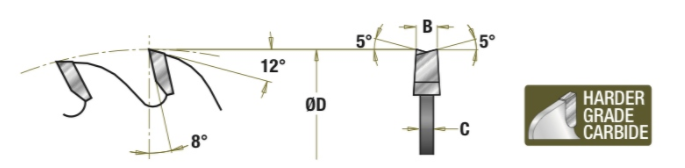

Item # DT120T24, Amana Tool Carbide-Tipped Ditec™ 2000 Conical/Adjustable Type Scoring 120mm Dia x 24T ATB, 8 Deg, 20mm Bore, Scoring Set

Thank you for shopping with us!

Used on panel saws with separate scoring units for chip-free cuts on both sides of the material. With conical type scoring blades, the kerf width changes with depth of penetration. Used in combination with our industrial saw blades '7' series only (#714721), etc). Also used in combination with the Ditec™ series panel saw main blades. Kerf range should match the main blade.

√ Exclusive DITEC™ Carbide Tips

√ Higher Reliability & Lower Maintenance

√ Low Noise Level

√ Laser Cut Saw Bodies

√ Excellent Cutting Quality

Instructions for grinding: For maintenance grinding, use fine grit (D400 to D600) diamond wheels. To match the factory grind, use a slower than normal feed rate. Damaged teeth can be replaced by any grade of carbide tooth. Replacing of a large number of teeth will, of course, shorten the life of the saw blade. Since the carbide in the DITEC™ is harder than other carbides, it is critical that you protect them from “thermal shock” if an adjacent tooth is replaced. Heat absorbed during the brazing process will seriously degrade the DITEC™ carbide.

Warning: Before use, read saw blade safety guidelines in Amana's catalog.

Used on panel saws with separate scoring units for chip-free cuts on both sides of the material. With conical type scoring blades, the kerf width changes with depth of penetration. Used in combination with our industrial saw blades '7' series only (#714721), etc). Also used in combination with the Ditec™ series panel saw main blades. Kerf range should match the main blade.

√ Exclusive DITEC™ Carbide Tips

√ Higher Reliability & Lower Maintenance

√ Low Noise Level

√ Laser Cut Saw Bodies

√ Excellent Cutting Quality

Instructions for grinding: For maintenance grinding, use fine grit (D400 to D600) diamond wheels. To match the factory grind, use a slower than normal feed rate. Damaged teeth can be replaced by any grade of carbide tooth. Replacing of a large number of teeth will, of course, shorten the life of the saw blade. Since the carbide in the DITEC™ is harder than other carbides, it is critical that you protect them from “thermal shock” if an adjacent tooth is replaced. Heat absorbed during the brazing process will seriously degrade the DITEC™ carbide.

Warning: Before use, read saw blade safety guidelines in Amana's catalog.

| SPECIFICATIONS | |

| Diameter | 120 mm |

|---|---|

| Bore | 20mm |

| Grind | Conical |

| Kerf | 4.4mm to 5.4mm |

| Machine | Altendorf , Martin, SCMI |

| Plate | 2.8 mm |

| Teeth | 24 |

| Manufacturer | Amana Tool |