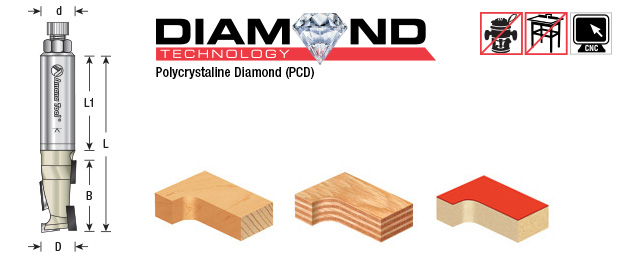

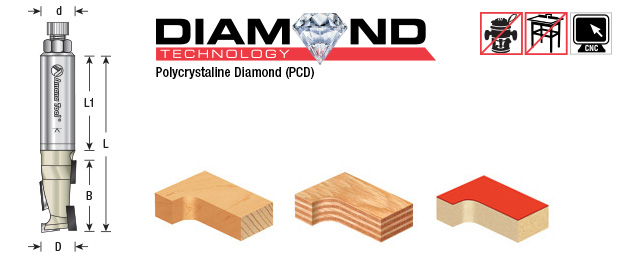

Item # DRB-216, Amana Tool CNC Polycrystalline Diamond (PCD) Tipped Compression Up/Down Shear R/H Direction 5/8" Dia x 1 5/8" CH x 5/8" Shank Router Bit (Industrial)

$228.02

Thank you for shopping with us!

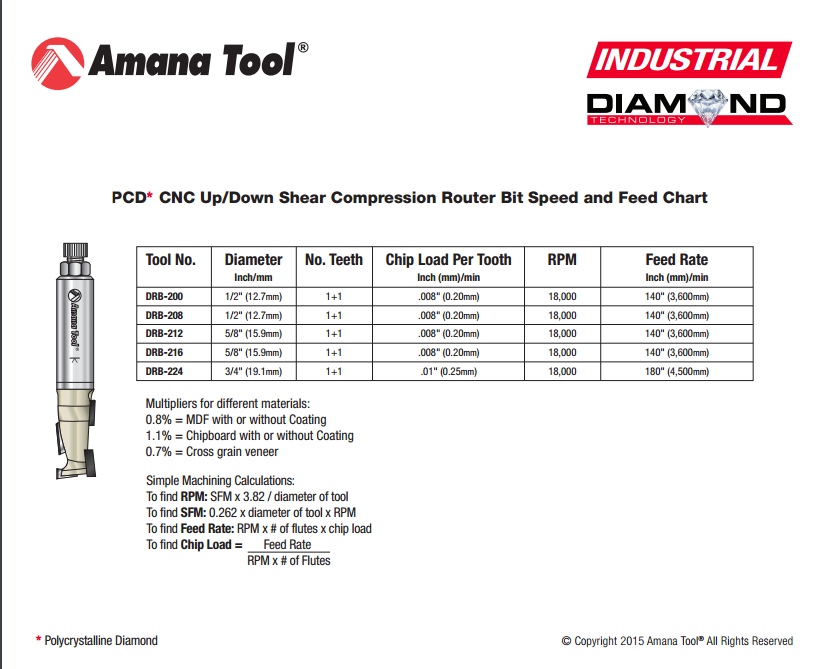

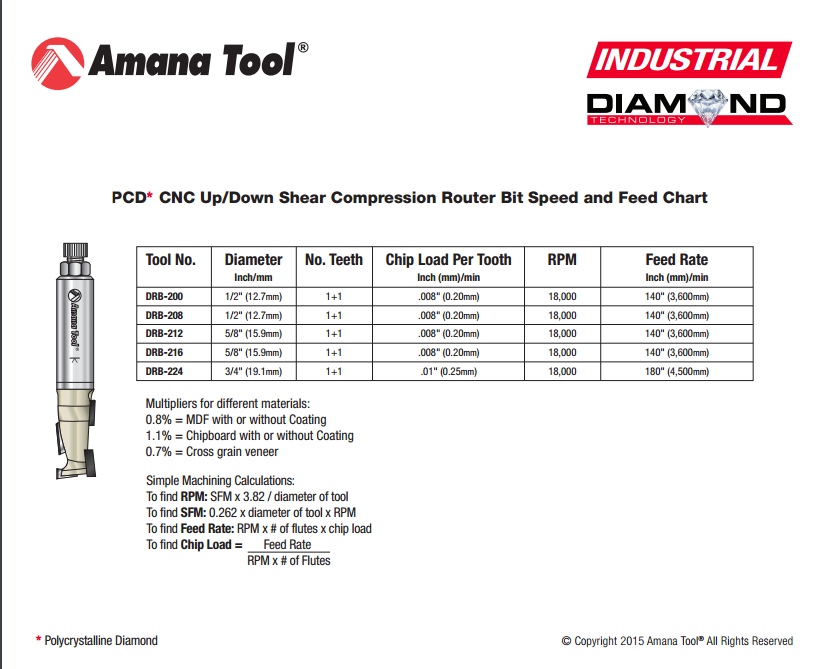

Diamond is the hardest naturally-occurring material on the earth. Polycrystalline Diamond (PCD) tooling is manufactured in a high-temperature and high-pressure laboratory that fuses diamond particles onto a carbide substrate, which allows the diamond to be brazed onto a tool body.

If you're looking for the ultimate in tooling, you've found it. Our diamond router bits will cut a wide variety of tough, abrasive materials. The cutting edge lasts up to 100 times longer than carbide; in the long-run, PCD is the most economical choice. Diamond-tipped compression with carbide plunge point router bits for grooving, jointing & rabbeting in composites, MDF (both raw or with melamine), laminate, plastic, wood, veneers, and more. Up/Down-shear for double-sided material.

Excellent for Cutting:

Diamond is the hardest naturally-occurring material on the earth. Polycrystalline Diamond (PCD) tooling is manufactured in a high-temperature and high-pressure laboratory that fuses diamond particles onto a carbide substrate, which allows the diamond to be brazed onto a tool body.

If you're looking for the ultimate in tooling, you've found it. Our diamond router bits will cut a wide variety of tough, abrasive materials. The cutting edge lasts up to 100 times longer than carbide; in the long-run, PCD is the most economical choice. Diamond-tipped compression with carbide plunge point router bits for grooving, jointing & rabbeting in composites, MDF (both raw or with melamine), laminate, plastic, wood, veneers, and more. Up/Down-shear for double-sided material.

Excellent for Cutting:

- Fiberglass Reinforced Composites

- Lightweight composites

- Custom composite materials

- Fiber-reinforced urethane

- Fiber-reinforced structural foam floors

- And More . . . .

Benefits of Diamond Technology

- Improved cycle times by enabling high material removal rates

- Faster speeds and feeds compared to conventional cutting tools

- Improved workpiece quality with tight dimensional control

- Optimized machine tool efficiency by increasing production capacity

- Consistently good component surface finish

- Can be reground up to 5 to 7 times

- Wear rate is much less than the carbide-tipped tools

| SPECIFICATIONS | |

| Manufacturer | Amana Tool |

|---|---|

| Diameter | 5/8 in |

| Flute Geometry | Upcut/Downcut |

| Flute | 1+1 |

| Length | 1 3/4 in Shank Length |

| Overall Length | 4 in |

| Rotation | Right |

| RPM | 27,000 |

| Shank | 5/8 in |

| Style | Compression with carbide plunge point |